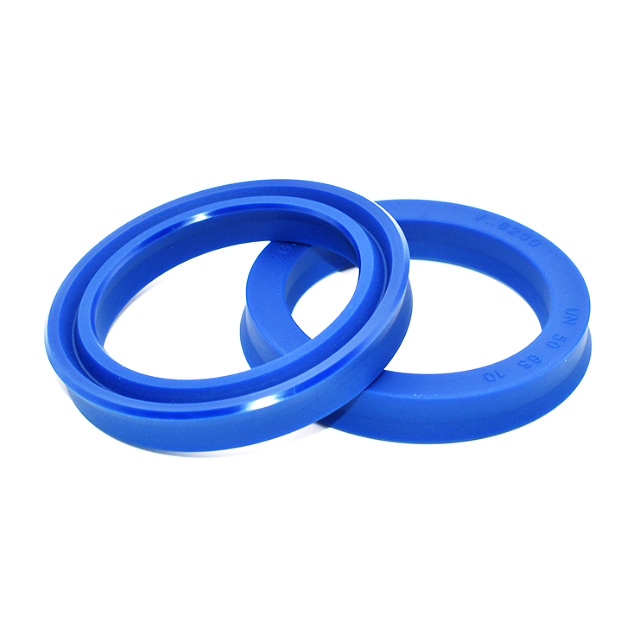

DKB oil seal and DKBI oil seal difference, DKB/DKBI is a double-lip dust seal to prevent entry of dust and protect equipment and maintain sealing performance of packings.

The difference between type of DKB & DKBI is the material for lip. DKB lip material is rubber (NBR), DKBI lip material is PU.

The DKB seal is mainly used for sealing non-pressure, non-rotating and low-speed dynamic sealing occasions. It is generally used for the dust-proof sealing of the rotating shaft of the machine. The seal has good dust-proof and wear-resistant performance, and has the characteristics of simple structure, low cost and easy installation.

The DKBI seal is mainly used for sealing non-pressure, rotary and low-speed dynamic sealing occasions. It is generally used for the dust-proof sealing of the rotating shaft of the machine, such as the dust seal of the bearing, the dust seal of the gearbox, and the dust seal of the oil tank. The seal has good dust-proof and wear-resistant performance, and has the advantages of low friction coefficient, no oil leakage, no damage to the shaft surface, and long service life.

In summary, the difference between DKB and DKBI oil seals is that the former has rubber lips and is mainly used for non-pressure, non-rotating and low-speed dynamic sealing, while the latter has PU lips and is mainly used for pressure, rotating and low-speed dynamic sealing. Both seals can prevent dust from entering the equipment and maintain the sealing performance of the packings.

As an oil seal manufacturer, we summarize some characteristics according to the experience of manufacturing oil seals:

1. The material of the DKB oil seal is rubber (NBR), and the material of the DKBI oil seal is PU. The DKBI oil seal has better wear resistance, oil resistance, and heat resistance than the DKB oil seal.

2. The DKB oil seal is mainly used in low-pressure and low-speed occasions, while the DKBI oil seal is suitable for medium and high pressure and medium and high speed occasions.

3. The DKB oil seal is suitable for dry and clean environments, and the DKBI oil seal is suitable for wet, dust and other harsh environments.

4. The DKB oil seal has a simple structure, and the DKBI oil seal has a more complicated structure, which is more effective in preventing dust infiltration.

5. The DKB oil seal is cheaper than the DKBI oil seal in terms of cost. In summary, DKB/DKBI oil seals are an ideal choice for dust-proof and air-tight sealing in a variety of industrial applications.

The choice of the oil seal depends on the specific application, the type of environment, the pressure, the speed and the cost.