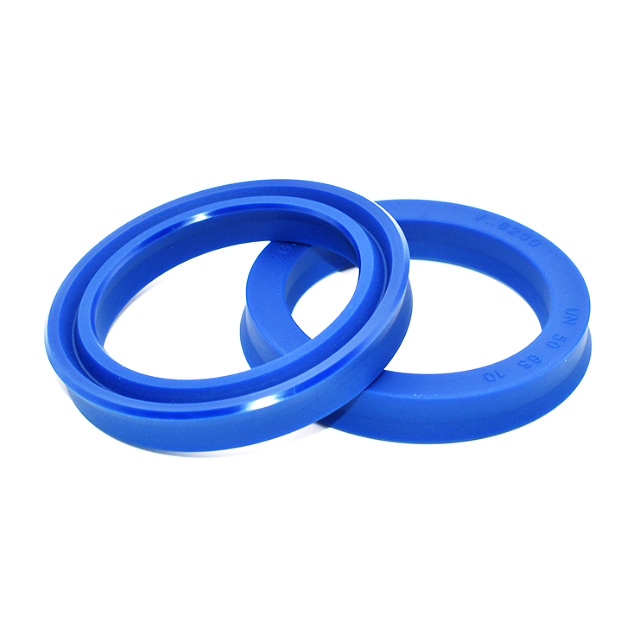

Seal want to maintain good sealing performance, you need to pay attention to these problems.

1. Temperature

The frozen rubber seal will become brittle and reduce its elasticity, resulting in air leakage.

In the process of moving, high temperature will cause the rubber seal to expand and become soft, causing the friction resistance of the rubber seal to increase rapidly and the pressure resistance performance to decrease.

It is recommended that the working temperature of the rubber seal is -10℃~+80℃.

2. Pressure

The cylinder has starting pressure, working pressure and impact force. Low-voltage operation requires a seal with poor friction performance and low starting resistance. Under high pressure, it is necessary to consider the compression deformation of the rubber seal, and an anti-extrusion support ring is required.

In addition, the working pressure range of rubber seals of different materials is different.

Rubber seals with a maximum pressure range of 25~315bar. To improve the compressive performance, a high-strength rubber back support ring and a unique lip design can be used to improve the ability to withstand a certain pressure.

3. Working medium

In addition to strictly following the working medium recommended by the manufacturer, it is also important to keep the working medium clean.

The residual air in the cylinder is formed by high-pressure compression. The high temperature causes the seal to burn out and even carbonize.

In order to prevent the occurrence of this problem, in the early stage of hydraulic system operation, exhaust treatment must be carried out. The hydraulic cylinder should also run slowly for a few minutes when the air pressure is low, and it can work normally after confirming that the air in the cylinder has been discharged.

4. pressure shock

The pressure will have a great impact on the cylinder, except for the high pressure and large flow hydraulic system, when the actuator is reversing, if the performance of the reversing valve is not good or the design is improper, it is easy to produce hydraulic shock. Such high pressure is extremely high.

In a short time, the rubber seal will be squeezed into the gap, or the sealing cover will be torn, causing serious damage to the rubber seal.