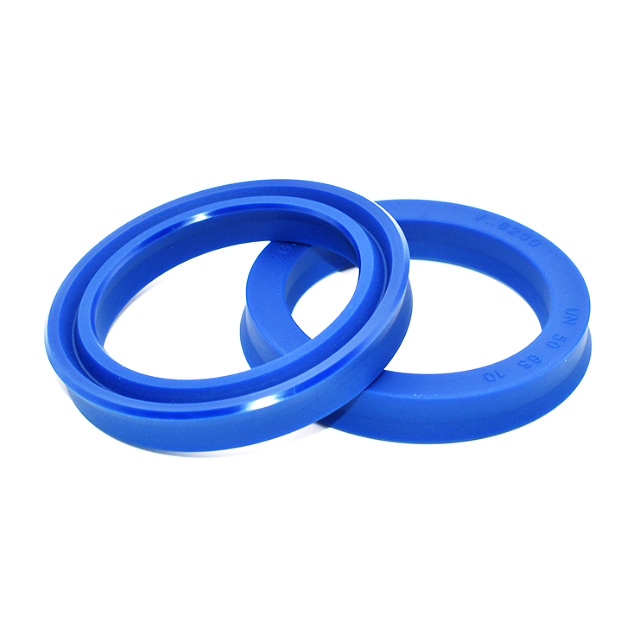

In the process of producing rubber seals, there will be certain product burrs on the products after the rubber seals are formed. Need to deal with burrs, let’s take a look at the relevant processing methods, and understand the relevant instructions together.

After the rubber seal is made and molded, there will be certain product burrs on the product. On the one hand, the rough edge treatment of rubber seals has high requirements on the appearance of the product, and on the other hand, it has an inevitable relationship with the product price. Generally, the processing process of rubber seal burrs also has a certain production cost for manufacturers. Therefore, on the premise of ensuring product quality in the process of processing burrs, manufacturers pay more attention to the processing efficiency of rubber seal burrs.

One of the treatment methods for the burrs of rubber seals: manual trimming. This method is labor-intensive, low-efficiency, and low-qualified. The second method of burr processing of rubber seals: mechanical trimming, mainly including punching, grinding wheel edging and round knife trimming, which is suitable for specific products with low precision requirements. The third method of processing the burrs of rubber seals: frozen trimming, special frozen trimming machine equipment, the principle is to use liquid nitrogen (ln2) to make the burrs of the finished product brittle at low temperatures, and use specific frozen particles (projectiles) to attack Beat burrs to quickly remove burrs. Frozen trimming has high efficiency, low cost, and a wide range of applicable products, which has become the mainstream process standard