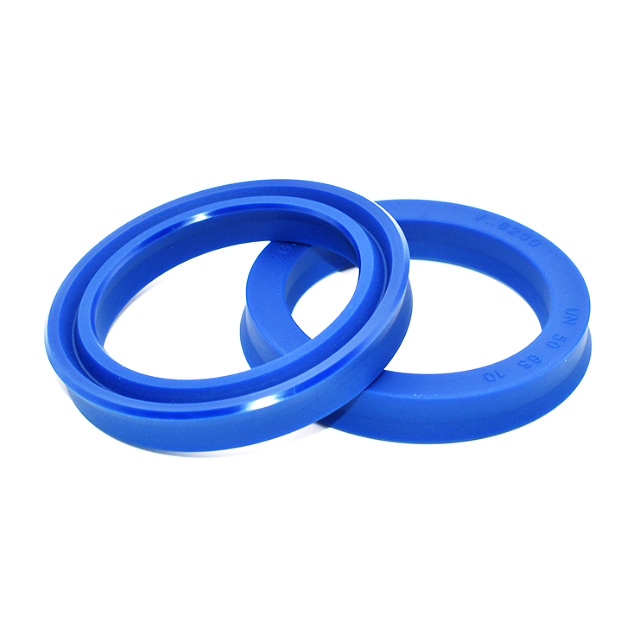

The function of the oil seal is to stop whatever fluid is inside from leaking out the clearance between the shaft and housing. The seal may also be used to prevent outside materials, such as dirt, from moving in through the clearance.

Most of you will already understand these basics of how an oil seal is designed but we wanted to put this tip out for people new to the field.

In an oil seal environment there is a shaft that is rotating inside a housing or bore. Because of friction, there must be some clearance between the shaft and the bore. The function of the oil seal is to stop whatever fluid is inside from leaking out the clearance between the shaft and housing. The seal may also be used to prevent outside materials, such as dirt, from moving in through the clearance.

“Dynamic sealing” is the relationship between the rotating shaft and the seal and is handled by the sealing element. A garter spring may used in the oil seal to increase the radial interference between the seal lip and contact point on the shaft. In order to achieve this interference, the oil seal’s ID must be slightly smaller than the diameter of the shaft.

“Static sealing” is the relationship between the housing and the seal. In order to achieve this interference, the oil seal’s OD must be slightly larger than the diameter of the housing or bore.

An oil seal normally consists of three basic components: the sealing element, the metal case and the spring. The purpose of the sealing element is to stop the fluid from leaking between the shaft and housing. The metal case will give rigidity and strength to the seal while it is being held in the bore or recessed groove. The spring will help make the sealing element more effective. All materials must be selected depending on the environment in which the oil seal will function.